- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

New Holland Pro-Belt™ Round Balers - Pro-Belt™ 450 CropCutter®

|

DIAMETER (IN. (CM)) 35.5 – 65 (90 – 165) WIDTH (IN. (CM)) 47.5 (121) | |

PROFESSIONAL PRODUCTIVITYPro-Belt™ Series round balers deliver maximum dependability and performance to enhance the productivity of professional haymakers and contractors. | |

INDUSTRY-LEADING WARRANTYBale with even more confidence. Pro-Belt round balers are backed by an industry-leading 2-year/15,000 bale base warranty, a 3-year/22,500 bale pickup warranty, and a 3-year/15,000 bale belt warranty. | |

COMMERCIAL-GRADE CONSTRUCTIONHeavy-duty components, like the smooth TwinDrive™ gearbox, thick steel frame, and simple chamber design lead to ideal bale density and commercial-grade longevity. | |

PRECISION TOOLS THAT IMPROVE PERFORMANCEPrecision solutions, like IntelliBale™ baler automation, in-cab density control, and factory-installed moisture sensing help you work smarter and produce better bales. |

EFFICIENT MAXISWEEP™ PICKUPA baler with a big appetite is nothing without a pickup and feeding system that can keep it full. The path to perfect, square-shouldered bales starts with the heavy-duty MaxiSweep pickup. The reliable twin-cam drive, 160 tines, and five-bar reel deliver a clean sweep, high capacity, and the strength to handle big windrows at a fast pace. To improve visibility and crop flow, the pickup mounting angle is moved forward slightly and the roller and tine windguard is fully adjustable. | |

ROLL WITHOUT THE BUNCHES

| |

AUGERS THAT DELIVER MAXIMUM THROUGHPUT

| |

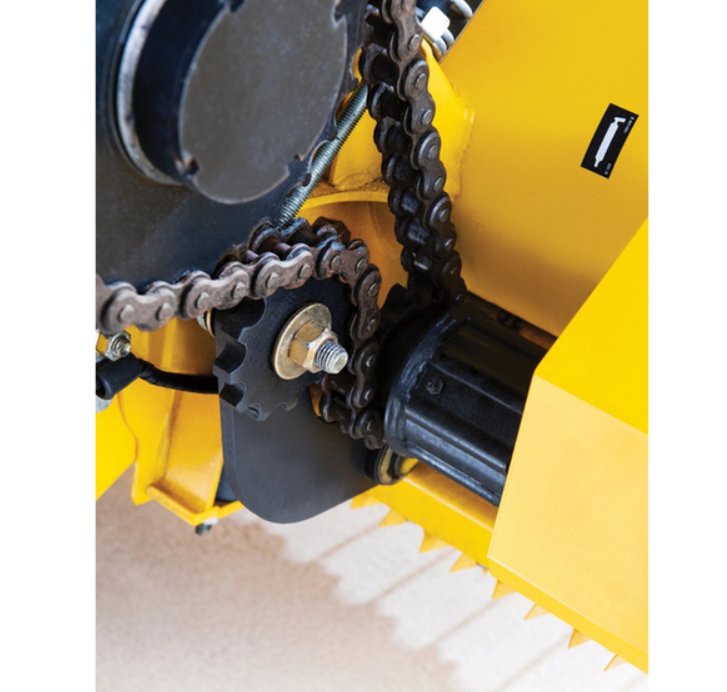

LINKED TO MORE BENEFITS

| |

FROM FIELD MODE TO ROAD IN A FLASH

|

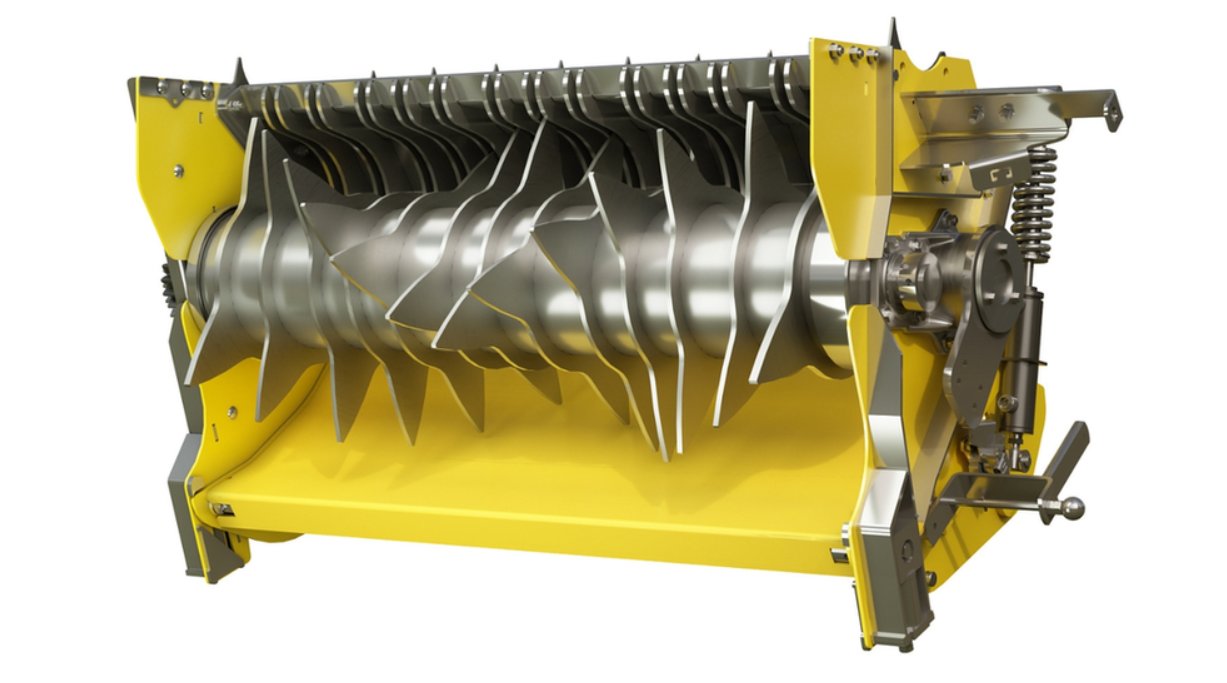

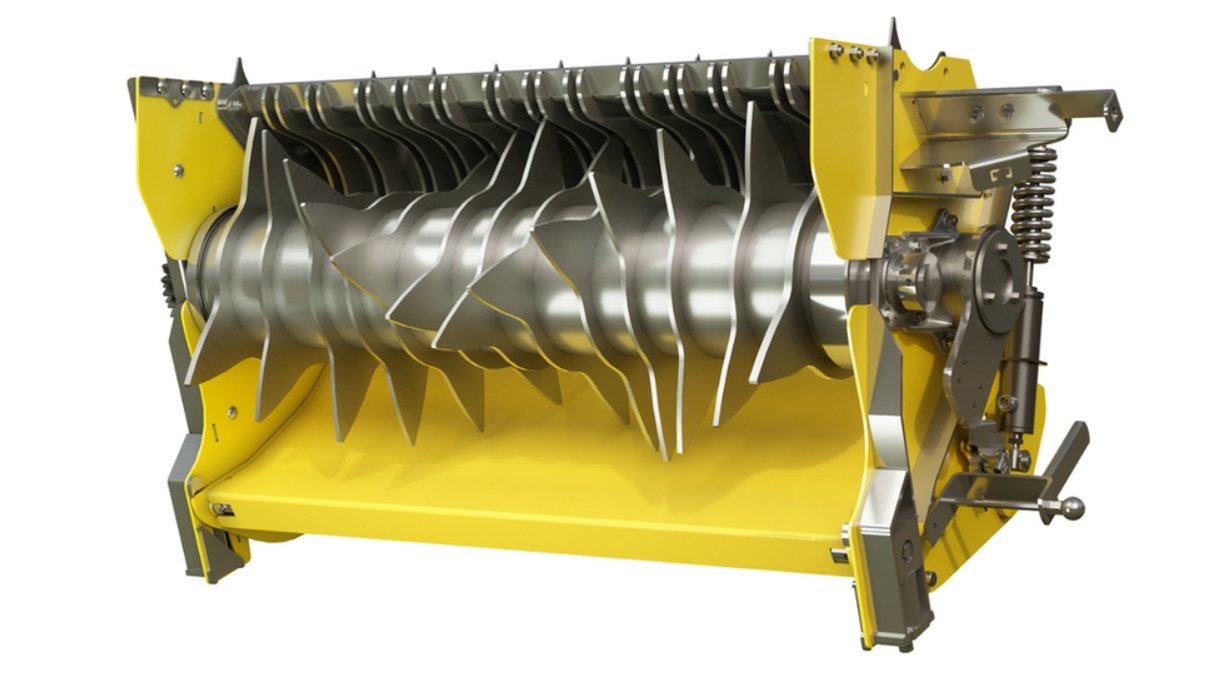

FEEDING AND CUTTING EXCELLENCEFor greater capacity, the SuperFeed™ rotary feeding system and CropCutter® rotary feeding and cutting system both feature a large, 20.5-inch diameter feeder that’s both 14% larger and double the weight of equivalent Roll-Belt™ models. These rotors offer smooth, “V”-shaped feeding to ensure that crop is directly power-fed across the full width of the chamber to provide excellent feeding and cutting for a baler with a big appetite. | |

SUPERFEED™ ROTARY FEEDING SYSTEM

| |

CROPCUTTER® ROTARY FEEDING AND CUTTING SYSTEM

| |

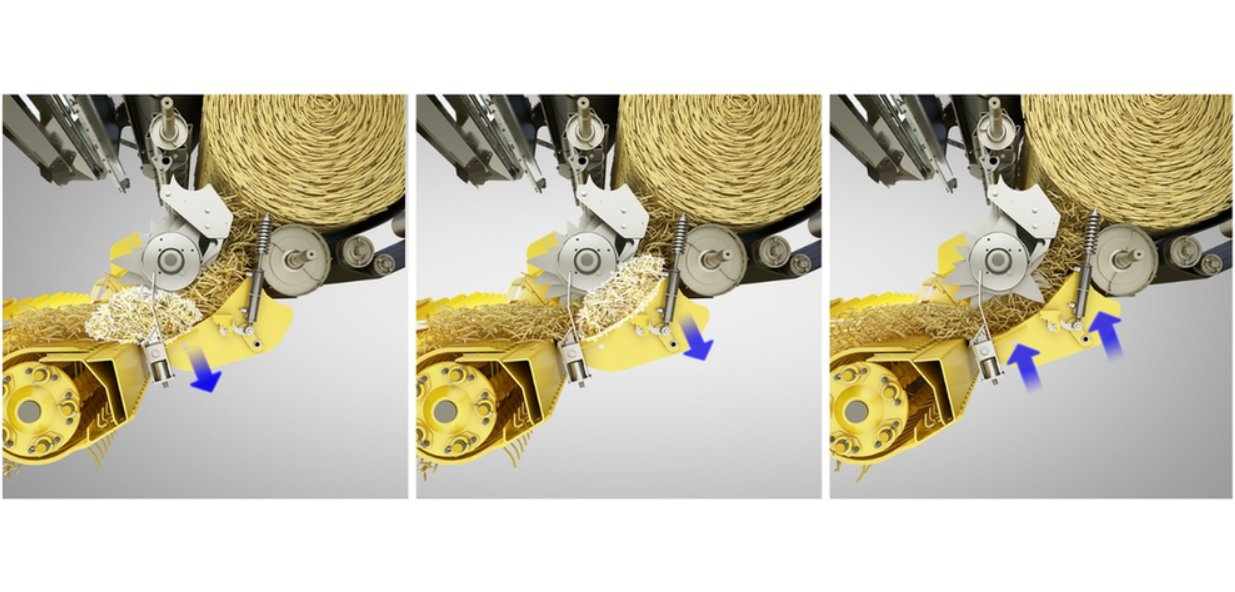

AUTOMATIC ACTIVEDROP™ FLOOR SYSTEM

|

|

Diameter (in. (cm)) |

35.5 – 65 (90 – 165) |

|

Length – tailgate closed (in. (cm)) |

192 (487) |

|

Height, tailgate closed, (in. (cm)) |

125 (317) |

|

Width (in. (cm)) |

47.5 (121) |

|

Max weight (lbs. (kg)) |

2879 (1305) |

|

Width – 500/55-20 tires (in. (cm)) |

108 (274) |

|

Width – 620/40-22.5 tires (in. (cm)) |

115 (292) |

|

Estimated shipping weight (lbs. (kg)) |

13 knife – 10,004 (4538) / 25 knife – 10,251 (4650) |

|

Width – inside/tine-to-tine (in. (cm)) |

81.7 (207.5) |

|

Width – outside/flare-to-flare (in. (cm)) |

89.6 (227.6) |

|

Number of tine bars |

5 |

|

Number of tines |

160 |

|

Speed (rpm) |

125 |

|

Dual no-tools gauge wheels |

Standard |

|

Dual no-tools castering gauge wheels |

Optional |

|

Design |

V-tine pattern |

|

Diameter (in. (cm)) |

20.5 (52) |

|

Speed (rpm) |

141 |

|

Single knife bank – number of knives |

13 |

|

Single knife bank – cut length (in. (cm)) |

3 (7.6) |

|

Activation |

Hydraulic |

|

Twin knife bank – number of knives |

25 |

|

Twin knife bank – cut length (in. (cm)) |

3 (7.6) or 1.7 (4.3) |

|

Activation |

Hydraulic (select on display) |

|

Knife protection |

Hydraulic accumulators |

|

ActiveDrop™ drop floor system |

Standard |

|

Floor roll |

Steel slatted |

|

Number of forming rolls |

2 |

|

Starter roll |

Steel segment-rib profile with rake scraper |

|

Fixed roll |

Steel segment-rib profile with rake scraper |

|

Maximum density pressure (psi (bar)) |

2320 (160) |

|

Number of belts |

4 |

|

Belt width (in. (cm)) |

11 (28) |

|

Number of belt drive rolls |

2 - 1 rubber covered, 1 smooth steel |

|

Net wrap |

EdgeWrap™ net wrap system |

|

Number of spare net rolls |

2 |

|

ISOBUS less display |

Standard |

|

IntelliView™ IV display |

Optional |

|

In-cab density and core controls |

Standard |

|

Factory moisture sensor (7-60% range) |

Optional |

|

500/55-20 |

Standard |

|

620/40-22.5 |

Optional |

|

PTO horsepower (minimum) |

110 – 120 |

|

PTO speed (rpm) |

1000 |

|

Hydraulic remote requirement |

2 |