- Monday 8:00 AM - 5:00 PM

- Tuesday 8:00 AM - 5:00 PM

- Wednesday 8:00 AM - 5:00 PM

- Thursday 8:00 AM - 5:00 PM

- Friday 8:00 AM - 5:00 PM

- Saturday 8:00 AM - 12:00 PM

- Sunday Closed

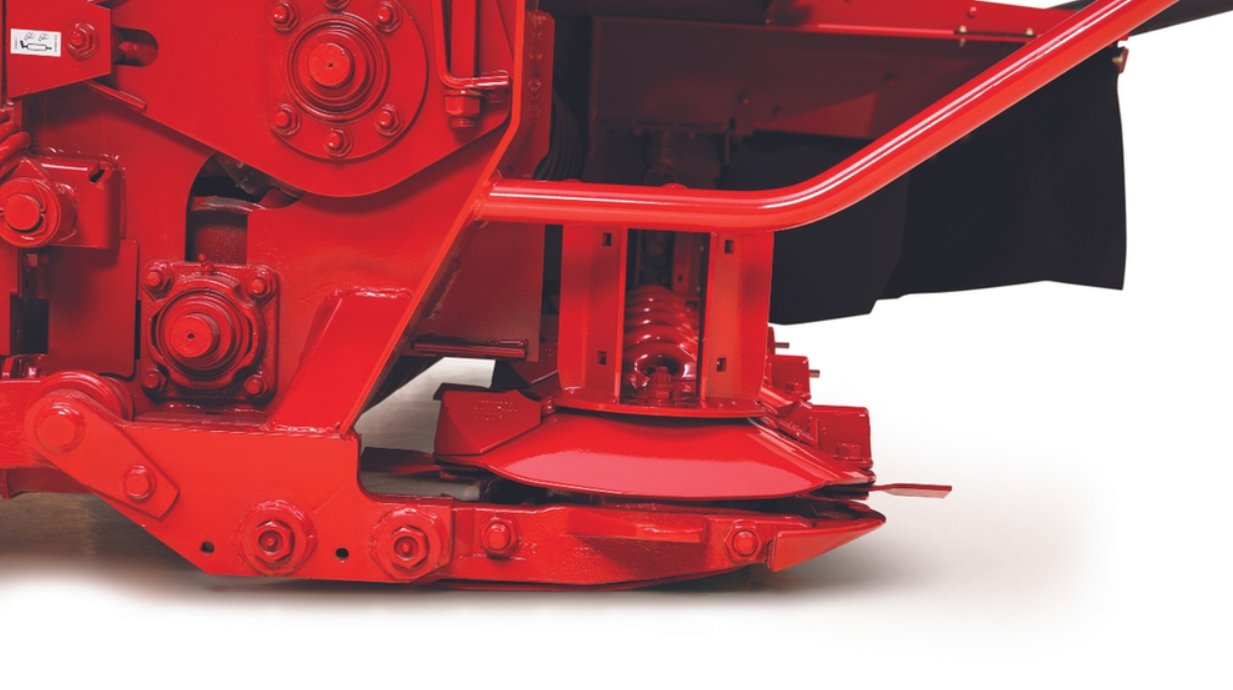

New Holland Discbine® Side-Pull Disc Mower-Conditioners - Discbine® 210

|

CUTTING WIDTH (FT. IN. (M)) 10’ 4” (3.16) NUMBER OF DISCS 8 | |

FAST, SMOOTH CUTTINGThe maneuverable 9’2” (2.8 m) Discbine® 209 and the 10’4” (3.16 m) Discbine® 210 make high-quality hay with the smooth, trouble-free performance you expect from a genuine Discbine®. | |

CUT WITH EVEN MORE CONFIDENCEFor ultimate peace of mind, a 2-year base warranty is standard along with an additional year of the MowMax™ cutterbar warranty so you can cut with even more confidence. | |

STANDARD QUICKMAX™ KNIFE CHANGE SYSTEMThe QuickMax knife change system makes it easy to keep knives sharp for the close, clean cut you want and increased tonnage. | |

HIGH QUALITY AND FAST DRYDOWNChoose the best conditioning system for your crops – rubber chevron rolls, steel chevron rolls or LeaningEdge™ flail tines. |

SAVE TIME AND MOW BETTER WITH THE QUICKMAX™ KNIFE CHANGE SYSTEMWhen you use sharp knives, you get a smooth finish, add tons to your harvest and improve the cut quality of future cuttings. With the QuickMax system, a special knife tool allows you to change bent or dull knives in less time than getting out of the tractor, so you save time and crop. |

|

Cutting width (ft. in. (m)) |

10’ 4” (3.16) |

|

Cutterbar model |

MowMax™ Modular Cutterbar with ShockPRO™ hubs |

|

Number of discs |

8 |

|

Knives per disc |

2 |

|

Disc speed @ 540 rpm PTO speed (rpm) |

3000 |

|

Tilt angle (degrees) |

2° - 10° |

|

Flotation |

Up & back, adjustable springs |

|

Drive method |

PTO drive with slip & overrunning clutch to bevel gearbox to LH end of header, vertical PTO shaft to cutterbar |

|

Cutting height (in. (mm)) |

Flail Tine: 1.1-2.7 (29-68) or Roll: .95-2.4 (24-60) |

|

Cutting height w/optional high-stubble shoes (in. (mm)) |

2.25-4.5 (58-115) |

|

Cutting height w/optional adjustable shoes (in. (mm)) |

2.25-4.5 (58-115) |

|

Type |

Chevron intermeshing rubber or steel rolls |

|

Length / Diameter (in. (mm)) |

102 (2591) / 10.4 (264) |

|

Drive method |

4 HB V-belt and enclosed gears |

|

Speed (rpm) |

647 |

|

Conditioner roll tension adjustment |

Single crank |

|

Conditioner gap adjustment |

Adjustable drawbolt stop, each end |

|

Type |

Flail rotor with 100 tapered flails |

|

Length / Diameter (in. (mm)) |

102 (2591) / 22 (560) |

|

Drive method |

4 HB v-belt |

|

Speed (rpm) |

718 standard, 1000 optional |

|

Conditioner gap adjustment |

Single crank adjustable rotor hood |

|

Swath width (ft. (m)) |

7 (2.13) |

|

Windrow width (ft. (m)) |

3-7 (0.9-2.13) |

|

Input speed (rpm) |

540 or 1000 Standard Drawbar Attachment, 540 Only Swivel Hitch Attachment |

|

Driveline protection |

Slip clutch and overrunning clutch assembly at rear of PTO shaft |

|

Secondary driveline |

Double CV Driveline - Head repositionable under load |

|

Type |

Side-pull, curved tongue |

|

Hitch type |

Standard Drawbar with CV PTO, Swivel hitch with drawbar adapter or 2-point hitch |

|

Minimum PTO power required (hp (kW)) |

80 (60) |

|

Hydraulic circuits required |

2 |

|

Minimum relief pressure required (psi (bar)) |

1500 (103) |

|

Drawbar |

ASAE Category II |

|

Swivel Hitch - Drawbar |

ASAE Category II or III |

|

Swivel Hitch - 2-Point |

ASAE Category II, III-N, or III |

|

Electrical |

7-pin electrical connector for transport lights |

|

Tubeless ag rib implement tires |

Standard hitch and flail conditioner: 9.5L x 14 6PR/ Swivel hitch and roll conditioner: 11L x 15 6PR |

|

Max road speed (mph (kph)) |

20 (32) |

|

Width, transport (ft. in. (m)) |

11’ 3” (3.42) |

|

Width , operating (ft. in. (m)) |

16’ 0” (4.87) / 17’ 7’’ (5.36), with swivel hitch equipped |

|

Length, transport (ft. in. (m)) |

Flail Tine: 18’ 1’’ (5.50)*** or Roll: 17’ 7’’ (5.23)*** |

|

Length, operating (ft. in. (m)) |

Flail Tine: 17’ 8’’ (5.4)*** or Roll: 15’ 7’’ (4.75)*** |

|

Height (ft. in. (m)) |

Transport: 5’ 3” (1.60) / Operating: 4’ 5” (1.35) |

|

Ground clearance with head fully raised (in. (mm)) |

Flail Tine: 17 (4.32) or Roll: 18 (4.57) |

|

Operating weight (lbs. (kg)) |

Flail Tine: 4100 (1864)*** / Roll: 4160 (1891)*** |